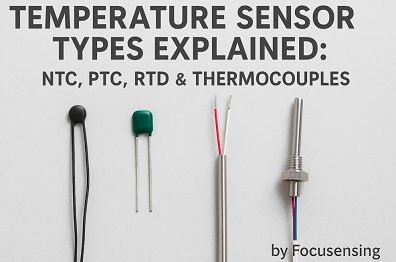

Temperature Sensor Types Explained: NTC, PTC, RTD & Thermocouples by Focusensing

Aug 14, 2025

As demand for industrial automation and smart devices continues to grow, the global temperature sensor market is expanding rapidly. According to industry reports, the market was valued at USD 7.699 billion in 2024 and is expected to reach USD 8.030 billion in 2025, surpassing USD 12.234 billion by 2035.

China-based Focus Sensing and Control Technology Co., Ltd. (Focusensing), with over 15 years of experience, has launched a comprehensive range of temperature sensor solutions, including NTC thermistors, PTC thermistors, RTDs, thermocouples, and digital sensors. These products target buyers in automotive, battery management, home appliances, medical devices, and industrial control sectors.

Common Temperature Sensor Types

Thermocouples use the voltage generated at the junction of two dissimilar metals to measure temperature, offering an extremely wide range (-200°C to 2300°C). They are cost-effective, heat-resistant, and vibration-proof, making them ideal for furnaces, exhaust systems, and metallurgy. Focusensing offers industrial-grade K-type and J-type thermocouples with reinforced designs for harsh environments.

RTDs use platinum elements whose resistance changes linearly with temperature, providing excellent stability and precision. Common types include Pt100 and Pt1000. Focusensing produces both thin-film and wire-wound RTDs, widely used in food processing, petrochemical control, and medical equipment.

Negative Temperature Coefficient (NTC) thermistors decrease in resistance as temperature rises. They are highly sensitive, cost-efficient, and fast-responding, making them perfect for household appliances, electronics, and battery monitoring. Focusensing’s NTC range includes epoxy-coated, glass-encapsulated, and digital-output models.

Positive Temperature Coefficient (PTC) thermistors increase in resistance with rising temperatures, sharply above a threshold, making them ideal for overcurrent protection and self-regulating heaters. Focusensing’s PTC sensors are used in automotive circuits, home appliances, and industrial systems.

Digital sensors (e.g., DS18B20, MCP9808) output direct digital signals for easy integration with controllers. Focusensing’s board-mount modules are widely used in IoT devices and smart meters.

By Sensor Type: Thermocouples account for 41.2% of the market, thanks to their versatility and low cost.

By Connectivity: Wired sensors dominate at 65.8% due to reliability and interference resistance.

Extensive Product Line: From NTC/PTC thermistors to RTDs, thermocouples, and digital modules.

Customization: OEM/ODM options for elements, ranges, housings, and connections.

High Accuracy & Reliability: Strict testing ensures stability under extreme temperatures and conditions.

Global Certification: ISO 9001, RoHS, REACH, and CE/UL compliance.

Q1: How do I choose the right temperature sensor?

A: Consider range, accuracy, speed, environment, and cost. For extreme heat, choose thermocouples; for high precision, RTDs; for quick, low-cost readings, NTC; for safety cut-offs, PTC; for digital integration, digital IC sensors.

Q2: What’s the difference between NTC and PTC thermistors?

A: NTC decreases resistance with heat (ideal for measurement), PTC increases resistance sharply above a set temperature (ideal for protection).

Q3: What models does Focusensing offer?

A: Epoxy and glass NTC thermistors, threaded NTC probes, clamp sensors, Pt100/1000 RTDs, K/J thermocouples, DS18B20 modules, and more—available in standard or custom designs.

Q4: Where are these sensors used?

A: Automotive, home appliances, industrial manufacturing, medical devices, power systems, and renewable energy applications.