Categories

Electric Vehicle Thermal Management System

March 31 , 2023Electric Vehicle Thermal Management System

TMS is generally used for batteries that operate at high discharge rates, especially large battery packs that require long life cycles (>10 years) and are costly to replace. For example, due to high battery maintenance costs, high vehicle costs per SE and relatively low vehicle replacement rates, all HEVs, PHEVs and EVs must be equipped with a Thermal Management System (TMS). In recent years, various research groups around the world have tried and tested several technologies that can easily remove heat from the battery pack. As you can seen, they can be classified in a number of ways.

Factors traditionally considered in TMS trade-off analyses include energy efficiency, capital cost, ease of operation, maintenance requirements and reliability. Cold plate and thermoelectric devices are not recommended for commercial systems due to their high thermal resistance and low coefficient of performance, respectively.

However, Gentherm Incorporation is using thermoelectric devices in its commercial designs and cold plates for the GMC Volt and Tesla Model S battery packs, indicating that both technologies have improved significantly in recent times. Temperature range and temperature variation are two key parameters that affect the performance of a battery pack. Ambient temperatures can vary from -35 to +50 degrees Celsius. Celsius in different regions, climates and seasons, while the required temperature range for the battery is approximately +15 to +35 degrees Celsius.

In addition, cell inconsistencies and thermal boundary conditions can lead to temperature differences between cells in a battery pack. These important issues require well-designed battery thermal management systems (BTMS). Traditional thermal management systems, such as fans and cooling panels, either have low scalability or provide marginal performance (estimated from a combination of cooling levels and regeneration rates) under challenging conditions. Other interesting alternatives (e.g. thermo-acoustic, magnetic, etc.) are available but have not yet reached full technical maturity.

It can therefore be concluded that a robust modular Thermal Management System (TMS) will be a hybrid system designed by combining at least two different TMS. Considering the technical risks, ease of integration, cost and energy efficiency, it can be concluded that the PCM will be an integral part of the modular TMS component.

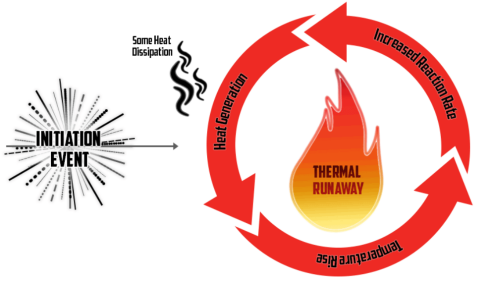

Thermal runaway occurs when the heat generated inside the battery exceeds the heat dissipated to the environment. What causes a battery to overheat and cause thermal runaway? -- Ambient temperature, battery age, float voltage, overcharging.

Ways to minimise thermal runaway: The reduction of thermal runaway can be achieved at three levels:

First, improving the intrinsic safety of TR resistance through material modification;

Second, establishing passive defences against actual misuse and developing pre-TR warning algorithms;

Third, delaying or preventing secondary hazards, such as thermal runaway propagation, to give passengers sufficient time to escape from the vehicle after an accident.

We believe that the three-stage safety design concept can significantly contribute to reducing the risk of hot runways in accidents. Researchers should be fully aware of the three-stage safe design concept to prepare for the coming era of higher energy density lithium-ion batteries.